The efficient assembly of functional molecules is a vital component of our modern day lives. The vast majority of healing drugs, agrochemicals that protect and guarantee our food supply, commodities, plastics and polymers of all types are all synthesised materials.

The efficient assembly of functional molecules is a vital component of our modern day lives. The vast majority of healing drugs, agrochemicals that protect and guarantee our food supply, commodities, plastics and polymers of all types are all synthesised materials.

Innovative methods to prepare these compounds and their necessary enabling tools must now conform to a more sustainable chemical agenda whereby we are more responsible for our actions. Flow chemistry methods, and particularly those developed to achieve multi-step processes, are beginning to have an impact on how we conduct chemical synthesis.

The ability to safely contain and manipulate molecules in the flow chemistry environment can lead to lower energy consumption, lower solvent use and recognisable gains in the more efficient employment of the scientific workforce by relegating mundane and trivial tasks to a more machine-assisted approach to chemical preparation. These new flow tools provide further opportunities through rapid reaction optimisation and development of seamless scale-up, containment of hazardous intermediates, and ease of operation for multiphase processes. Increasingly inline tools to better analyse reaction pathways and greatly improve downstream unit operations together with remote monitoring and control are helping develop our vision for a ‘lab of the future’.

Lab of the Future - Augmented Reality for Enhanced Chemical Communication

Computational chemistry uses computer simulation to solve chemical problems. Based on decades of synthetic experience in the Ley group, we are aiming to create a general and comprehensive approach to rationalise organic reactivity and predict new reactions using computational chemistry tools. We are currently looking into the following reactions in relationship to flow chemistry platforms:

- Predicting regioselectivity of lithiation reactions

- Formation of substituted benzynes from α-lithiated aromatic halides

- Mechanistic studies to rationalise and predict reactivity of

nitriles in silico - SAR relationships for the nucleophilic difluorination of carbonyl compounds

Augmented Reality for Enhanced Chemical Communication

Augmented Reality (AR) is a new technology as well as a field of research sitting at the interface of Virtual Reality (VR), Artificial Intelligence (AI) and Computer Graphics (CG). In AR applications, artificial data are overlaid on to the real world environment, therefore endowing it with additional information in a new interactive manner. The widespread adoption of increasingly powerful and compact computing devices provides great potential for the development of new powerful applications in many areas. AR has already impacted chemistry for educational purposes, but we believe that this technology will become a valuable tool for enhanced illustration of chemical communications.

We aim to develop fully automated procedures for chemists to visualise structures, molecular properties, reaction mechanisms and equipment used to perform flow chemistry processes. We are currently developing applications for the AR representation for:

- X-Ray diffraction data

- Computational chemistry studies

- 3D structure optimisation

- Conformational analysis

- Transition state search

- IRC (reaction pathway) calculations

- 3D structure of molecular orbitals

- 3D mapping of the electrostatic potential

- New flow laboratory equipment prototypes

CASP: Computer-aided synthesis planning

Our Computer Aided Synthesis Planning (CASP) programme aims to develop an integrated platform for chemical information resources: computational, experimental and database.

The resources will be interfaced using informatics tools, with the ability to process combined chemical information and transform data into a refined chemical knowledge to provide efficient solutions to chemical problems and to develop new processes. Although chemical information resources are well established and independent in their own right, our objective is to combine, analyse and extract the relevant knowledge from a large and different set of data. By applying informatics tools we will be able to combine both empirical and non-empirical data, classify, store, and identify patterns and trends to work out the key relationships among the obtained data.

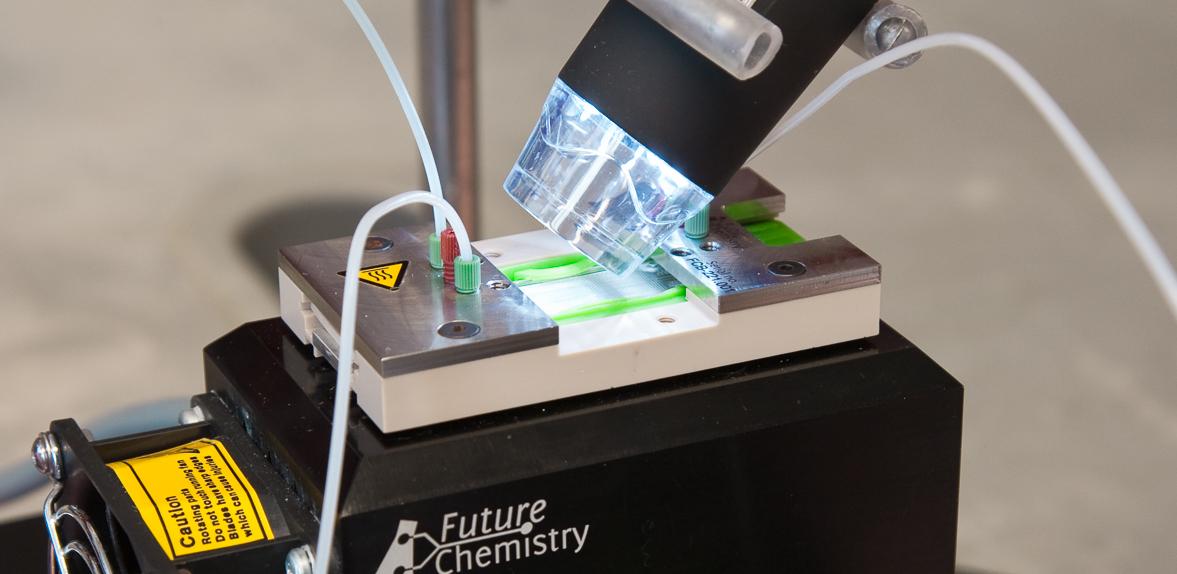

In-Line Liquid-Liquid Separation for Laboratory-Scale Continuous-Flow Synthesis

One of the key benefits of flow chemistry is amenability to automation. The Ley group has been a major proponent of using flow chemistry to simplify downstream processing by automating work-up procedures following flow reactions. In addition to developing solid-supporting reagents and scavengers and monoliths for this purpose, we have developed technologies for the automated mechanical separation of liquid phases.

In 2007, our research group reported the first use of the Syrris FLLEX liquid-liquid membrane-based extraction unit to automate the workup of alcohol alkylations as a proof-of-principle demonstration [1].

In 2012, we reported the development of a prototype camera-and-computer based gravity separation unit [2].

Shortly afterwards, we advanced this technology for multiple in-line liquid-liquid separations in series, allowing workups to be automated over >24 h periods on reactions of >20 g scales. (D.X. Hu, M. O’Brien, S.V. Ley).

For a video demonstration of this technology, see click here.

Publications

1. A microcapillary flow disc (MFD) reactor for organic synthesis, C.H. Hornung, M.R. Mackley, I.R. Baxendale and S.V. Ley and, Org. Proc. Res. Dev. 2007, 11, 399-405.

2. A prototype continuous-flow liquid–liquid extraction system using open-source technology M. O’Brien, P. Koos, D.L. Browne, S.V. Ley, Org. Biomol. Chem. 2012, 10, 7031-7036.

3. Continuous multiple liquid–liquid separation: diazotization of amino acids in flow D.X. Hu , M. O’Brien, S.V. Ley, Org. Lett. 2012, 14, 4246-4249.

Solvent Switcher/Evaorator

A meso-fluidic, multi-purpose continuous evaporator

Continuous solvent removal and switching is well established on a large industrial scale with falling film evaporators, cone evaporators and similar large scale devices serving the needs of the food, beverage, petroleum and other industries. On the other end of the spectrum, a number of forays have also been made into the design of microfluidic evaporator units but these have primarily been used as concentrators for specialised analytical devices. We believe there is a need to develop a general, multi-purpose evaporator for meso-fluidic processing in research laboratories which is compatible with existing flow chemistry equipment and with the typical product output from the reactors. Drawing inspiration from electrospray ionisation techniques, we envisaged a device which would expose a high surface spray of solution to a desolvation gas to remove solvent quickly and efficiently.

1 Omnifit® column 100 x 15 mm o.d.

2 Modified top end piece assembly

3 Bottom end piece assembly

4 PTFE end fitting

5 Connection cap

6 PTFE tubing 1/4” (6.35 mm) o.d. x 3/16” (4.8 mm) i.d.

7 Swagelok® Stainless steel Union tee, 1/4” (6.35 mm) tube o.d.

8 Swagelok® Stainless steel Bored-through Reducer, 1/8” (3.17mm) x 1/4” (6.35 mm) tube o.d.

9 Stainless Steel Tubing, 1/8″ (3.17mm) o.d. x 0.080″ (2.03mm) i.d.

10 Swagelok® Stainless stee Union tee, 1/8″ (3.17mm) tube o.d.

11 Swagelok® Stainless steel Bored-Through Reducer, 1/16″ (1.587mm) x 1/8” (3.17mm) tube o.d.

12 Stainless Steel Tubing, 1/16″ (1.587mm) o.d. x 1/200″ (0.127mm) i.d.

In our flow synthesis of the probe for the Neurotensin receptor-1, Meclinertant (SR48692), we reported the solvent switch from toluene to methanol in a multi-step flow sequence. For us this represented an unfortunate problem since both the previous acylation/rearrangement steps and the subsequent aromatisation/methylation were telescoped, the only break in the sequence being the necessity to remove toluene and subsequently re-dissolve 2-acetylcyclohexane-1,3-dione intermediate 1 in methanol. (Scheme 1)

Scheme 1. a) Semi-telescoped flow scheme for the synthesis of acetophenone 2 and b) graphical scheme for the solvent switch from toluene to MeOH involving intermediate 1, using our bespoke prototype.

Using our in-line evaporator prototype, a flowing solution of 1 in toluene was concentrated by the evaporator (0.13 mL/min) and enriched in MeOH (10:1 MeOH/toluene). The evaporator was run continuously for 1 hour and the resulting solution of 1 was fed directly into the subsequent steps of the flow synthesis of Meclinertant. (Scheme 1)

Publications

A prototype device for evaporation in batch and flow chemical processing B.J. Deadman, C. Battilocchio, E. Sliwinski, S.V. Ley, Green Chem. 2013, 15, 2050-2055.

A machine-assisted flow synthesis of SR48692: a probe for the investigation of neurotensin receptor-1 C. Battilocchio, B.J. Deadman, N. Nikbin, M.O. Kitching, I.R. Baxendale, S.V. Ley, Chem. Eur. J. 2013, 19, 7917-7930.

Gas Reactors

Gas reactors used continuous flow chemical synthesis

Our expertise in developing new enabling tools for continuous flow processes has led to significant advances in the way we conduct our synthesis programmes. We have delivered new concepts; from prototype to fully operational bench-top units. A novel tube-in-tube flow gas reactor (designed in house) has now been developed into a commercial product with Cambridge Reactor Design [1].

The use of gases or volatile components as reagents is often not ideal in batch mode operation due to safety concerns. However, using our semi-permeable membrane flow reactor device we have created a robust gas reactor that allows controlled solubilisation of gaseous reagents into a liquid stream to achieve a wide selection of reactions. We have disclosed a diverse range of applications using these devices to carryout ozonolysis [2], carboxylations [3], hydrogenations [4, 5], Glaser oxidative couplings [6],carbonylations [7], nucleophilic addition of ammonia [1, 8, 9], hydroformylations using Syngas [10], coupling Heck reactions using ethylene [11, 12], as well as aerobic anti-markovnikov oxidative processes [13]. We also developed a bespoke reactor system for the “spray ozonolysis” of one of the intermediate used in the synthesis of an unnatural amino acid [14].

Publications

1. Flow synthesis using gaseous ammonia in a Teflon AF-2400 tube-in-tube reactor: Paal–Knorr pyrrole formation and gas concentration measurement by inline flow titration P.B. Cranwell, M. O’Brien, D. L. Browne, P. Koos, A. Polyzos, M. Peña-López, S.V. Ley Org. Biomol. Chem. 2012, 10, 5774-5779,

2. Flow ozonolysis using a semi-permeable Teflon AF-2400 membrane to effect gas-liquid contact M.O’Brien, I.R. Baxendale, S.V. Ley Org. Lett. 2010, 12, 1596-1598.

3. The continuous flow synthesis of carboxylic acids using CO2 in a tube-in-tube gas permeable membrane reactor A. Polyzos, M. O’Brien, T.P. Petersen, I.R. Baxendale, S.V. Ley Angew. Chem. Int. Ed. 2011, 50, 1190-1193.

4. Asymmetric homogenous hydrogenation in flow using tube-in-tube reactor S. Newton, S.V. Ley, E.C. Arce, D. Grainger Adv. Synth. Catal. 2012, 354, 1805-1812.

5. Hydrogenation in flow: homogenous and heterogeneous catalysts using Teflon AF-2400 to effect gas-liquid contact at elevated pressure M. O’Brien, N. Taylor, A. Polyzos, I.R. Baxendale, S.V. Ley Chem. Sci. 2011, 2, 1250-1257.

6. The oxygen-mediated synthesis of 1,3-butadiynes in continuous flow: using Teflon AF-2400 to effect gas/liquid contact T.P. Peterson, A. Polyzos, M. O’Brien, T. Ulven, I.R. Baxendale, S.V. Ley ChemSusChem 2012, 5, 274-277.

7. Teflon AF-2400 mediated gas-liquid contact in continuous flow methoxycarbonylations and in-line FTIR measurement of CO concentration P. Koos, U. Gross, A. Polyzos, M. O’Brien, I.R. Baxendale, S.V. Ley Org. Biomol. Chem. 2011, 9, 6903-6908.

8. Continuous-flow processing of gaseous ammonia using a Teflon AF-2400 tube-in-tube reactor: synthesis of thioureas and in-line titrations D.L. Browne, M. O’Brien, P. Koos, P.B. Cranwell, A. Polyzos, S.V. Ley Synlett 2012, 23, 1402-1406.

9. Scaling-up of continuous flow processes with gases using a tube-in-tube reactor: in-line titrations and fanetizole synthesis with ammonia J. Pastre, D.L. Browne, M. O’Brien and S.V. Ley, Org. Proc. Res. Dev. 2013, 17, 1183-1191.

10. Syngas-mediated C-C bond formation in flow: selective rhodium-catalysed hydroformylation of styrenes S. Kasinathan, S.L. Bourne, P. Tolstoy, P. Koos, M. O’Brien, R.W. Bates, I.R. Baxendale, S.V. Ley Synlett 2011, 2648-2651.

11. The continuous flow synthesis of styrenes using ethylene in a palladium-catalysed Heck cross-coupling reaction S.L. Bourne, P. Koos, M. O’Brien, B. Martin, B. Schenkel, I.R. Baxendale, S.V. Ley Synlett 2011, 2643-2647

12. Flow chemistry syntheses of styrenes, unsymmetrical stilbenes and branched aldehydes S.L. Bourne, M. O’Brien, S. Kasinathan, P. Koos, P. Tolstoy, D.X. Hu, R.W. Bates, B. Martin, B. Schenkel, S.V. Ley, ChemCatChem., 2013, 5, 159-172.

13. A continuous flow solution to achieving efficient, aerobic anti-Markovnikov Wacker oxidation S.L. Bourne, S.V. Ley, Adv. Synth. Catal. 2013, 355, 1905-1910.

14. A flow based synthesis of 2-aminoadamantane-2-carboyxlic acid

C. Battilocchio, I.R. Baxendale, M. Biava, M.O. Kitching and S.V. Ley, Org. Proc. Res. Dev. 2012, 16, 798-810.

15. Flow Chemistry: Intelligent Processing of Gas-Liquid Transformations using a Tube-in-Tube Reactor M. Brzozowski, M. O’Brien, S.V. Ley, A. Polyzos, Acc. Chem. Res. 2015, 48, 349-362

Low Temperature Reactors

The use of cryogenic consumables to cool reactions is impractical on scale or over extended reaction times. We have recently published our work [1] that describes the development of a convenient laboratory device that offers chemists the benefits of continuous flow processing using an accurate thermal energy transfer block which provides long-term reaction stability and is free from water ingress.

These units have been designed to avoid the need for consumable cryogenic materials to deliver rapid reaction cooling down, and can provide cooling down to –89°C with little condensation or water ingress over prolonged periods (weeks).

We recently used this cryogenic flow reactor for the preparation of a variety of (hetero)aromatic boronic acids and esters via lithium halogen exchange chemistry [2], diasteroselective fluorination reactions [3], control over gas permeation through a Teflon AF-2400 membrane, preparation of biologically active materials [4] . Most recently we have been developing the use of thermocouples to monitor real time reaction exotherms, liquid-liquid separators to effect inline quenching and extraction, and the ability to monitor and even control the cooling power based on the liquid temperature at the point of mixing.

See Cambridge Reactor Design: FlowSyn Polar BearTM

Publications

1. Continuous cold without cryogenic consumables: development of a convenient laboratory tool for low temperature flow processes D.L. Browne, B.H. Harji, S.V. Ley, Chem. Eng. and Technol. 2013, 36, 959-967.

2. A new enabling technology for convenient laboratory scale continuous flow processing at low temperatures D.L. Browne, M. Baumann, B.H. Harji, I.R. Baxendale, S.V. Ley* Org. Lett. 2011, 13, 3312-3315

3. Studies of a diastereoselective electrophilic fluorination reaction employing a cryo-flow reactor K. Nakayama, D.L. Browne, I.R. Baxendale, S.V. Ley, Synlett 2013, 24, 1298-1302.

4. Scaling Up of Continuous Flow Processes with Gases Using a Tube-in-Tube Reactor: Inline Titrations and Fanetizole Synthesis with Ammonia J.C. Pastre, D.L. Browne, M. O’Brien, S.V. Ley, Org. Process Res. Dev. 2013, 17, 1183–1191

Integrated Bioessays

Frontal Affinity Chromatography (FAC)

Continuous methods and flow processing for chemical synthesis and biological evaluation are both now well established and documented. Our ultimate aim is to produce coordinated systems to achieve “Make & Screen” in flow, hence integrating of these devices in one single laboratory environment. When this powerful tool is combined with appropriate automated synthesis systems and design software, then a true closed loop discovery platform will be attained.

FAC is a biophysical method where the target macromolecule is immobilised on a polymeric support; the binding affinity of a compound can be measured by comparing its retention to that of a control. In our opinion, this simple and robust method is an ideal evaluation method that may be plugged in-line to our existing flow chemistry platforms.

Principle of Frontal Affinity Chromatography

Our proof of concept work was published early 2013, in which a library of GABAA agonists, including zolpidem (Stilnox, Ambien) and alpidem, were synthesised using flow chemistry. Binding affinities towards Human Serum Albumin (HSA, the most abundant protein in plasma) were accurately determined and in accordance with the literature. Furthermore, a simple ranking method based on aliquots automatically prepared via the flow platform showed good correlation with binding affinities and potential for full integration with our flow equipment.

Current FAC-MS set-up

We are now using Mass Spectrometry as detection system, which enables the injection of mixtures for competitive studies, and virtually detects any compound with no need of pre-labelling. Our current set-up is now applied to a medicinal chemistry programme in epigenetics: the discovery of bromodomains modulators. This research project is being run in collaboration with SGC (Structural Consortium Genomics, Oxford, www.thesgc.org), which kindly provides proteins of interest and cross-validates data.

Publications

Flow chemistry synthesis of zolpidem, alpidem and other GABAA agonists and their biological evaluation through the use of in-line frontal affinity chromatography L. Guetzoyan, N. Nikbin, I.R. Baxendale, S.V. Ley, Chem. Sci., 2013, 4, 764-769.

Inline IR Monitoring

Flow processing presents some unique analytical challenges when compared to their typical batch reaction equivalent. Corresponding innovative solutions and opportunities arise to solve these issues. Accordingly, we have entered into an early collaboration with expert manufacturers Mettler-Toledo to develop the FlowIR flow cell as a new device for in-line IR analysis. IR spectroscopy represents a non-destructive, substrate specific analytical technology that can be readily incorporated into flow chemistry sequences.

We have demonstrated the use of these new IR flow cells for reaction monitoring [1, 2], mechanistic investigations [3] and quantitative measurements of product dispersion during segmented flow [4, 5, 6]. This last application also facilitates additional pump control during multistep processing [7]. We have recently found it to be a useful tool to monitor the preparation and behavior of arylmagnesium reagents in flow [6].

Publications

1. ReactIR flow cell: a new analytical tool for continuous flow chemical processing

Org. Process Res. Dev. 2010, 14, 393-404

C. F. Carter, H. Lange, S. V. Ley*, I. R. Baxendale, B. Wittkamp, J. G. Goode, N. L. Gaunt

2. A continuous flow process using a sequence of microreactors with in-line IR analysis of the preparation of N, N-diethyl-4-(3-fluorophenylpiperidin-4-ylidenemethyl) benzamide as a potent and highly selective δ-opioid receptor agonist

Chem. Eur. J. 2010, 16, 12342-12348

Z. Qian, I.R. Baxendale, S.V. Ley*

3. Preparation of arylsulfonyl chlorides by chlorosulfonylation of in situ generated diazonium salts using a continuous flow reactor

Org. Biomol. Chem., 2010, 8, 5324-5332

L. Malet-Sanz, J. Madrzak, S.V. Ley, I.R. Baxendale

4. Fully automated, multistep flow synthesis of 5-amino-4-cyano-1,2,3-triazoles

Org. Biomol. Chem. 2011, 9, 1938-1947

C.J. Smith, I.R. Baxendale, H. Lange, S.V. Ley

5. Teflon AF-2400 mediated gas-liquid contact in continuous flow methoxycarbonylations and in-line FTIR measurement of CO concentration

Org. Biomol. Chem. 2011, 9, 6903-6908

P. Koos, U. Gross, A. Polyzos, M. O’Brien, I.R. Baxendale, S.V. Ley

6. Continuous preparation of arylmagnesium reagents in flow with inline IR monitoring

Org. Process Res. Dev. 2012, 16, 1102-1113

T. Brodmann, P. Koos, A. Metzger, P. Knochel,* S. V. Ley*

7. A breakthrough method for the accurate addition of reagents in multi-step segmented flow processing

Chem. Sci. 2011, 2, 765-769

H. Lange, C. F. Carter, M. D. Hopkin, S. V. Ley*

Microcapillary Reactors

Cambridge Disc Microreactor (CDM)

In collaboration with our Chemical Engineering colleagues we have developed a prototype continuous flow multi-channel microreactor [1] that is also capable of internal surface functionalisation with, for example, a palladium metal to achieve transfer hydrogenation reactions [2]. Simple chemical deposition techniques were used to deposit palladium(0) on the channel wall surface of a polymeric multi-capillary extrudate made from ethylene-vinyl alcohol copolymer. The palladium coating of the microcapillaries was characterized by mass spectrometry and light and electron microscopy.

In other work we present further proof of concept reactions for the CDM using plastic microcapillary flow discs (MFDs) [3]. These flat reactor discs were constructed from a flexible, temperature resilient, solvent resistant fluoropolymer microcapillary film comprising 10 parallel capillary channels. The MFDs can be heated within the microreactor via conductive heat transfer from two heated surfaces, which were in contact with the flat outer surfaces of the disc. This allowed continuous flow processing of liquid phase reactions through the reactor at elevated temperatures and pressures at a precisely controlled residence time. The process characteristics of the reactor system were established experimentally by investigating the hydraulic response and the temperature profile or modeled analytically such that the residence time characteristics inside the device could be predicted. A series of organic chemical reactions, namely electrophilic fluorination and the formation of various mono- and bicyclic heteroaromatic compounds, were conducted in the system at temperatures between 110 and 120 °C.

Publications

1. A microcapillary flow disc (MFD) reactor for organic synthesis

C.H. Hornung, M.R. Mackley, I.R. Baxendale and S.V. Ley

Org. Proc. Res. Dev., 2007, 11, 399-405.

2. A palladium wall coated microcapillary reactor for use in continuous flow transfer hydrogenation

Adv. Synth. Catal. 2010, 352, 1736-1745

C.H. Hornung, B. Hallmark, M.R. Mackley,* I.R. Baxendale and S.V. Ley*

3. Multiple microcapillary reactor for organic synthesis

Ind. Eng. Chem. Res., 2010, 49, 4576-4582

C.H. Hornung, B. Hallmark, M. Baumann, I.R. Baxendale, S.V. Ley, P. Hester, P. Clayton, M.R. Mackley

Flow Mixers and Agitators

Traditional methods for downstream processing of chemical reactions can be time-consuming and inefficient as reactions usually need quenching and further purification (a process that typically requires large quantities of solvents). While in batch mode, operations that involve slurries and solid precipitates can be accommodated using appropriate solid work-up facilities; serious problems can arise such as fouling and blocking during continuous flow mode operations or during telescoped reaction processes. Since flow chemistry and microreactor technology are making a significant impact on the praxis of organic synthesis, we have devised simple, but effective prototype devices to overcome some of the problems associated with flow chemistry methods when slurries or solid particulates are involved.

The first of these we define as the MFIFM (magnetic field induced flow mixer) shown schematically above and in use (below). This new device, designed for agitating and lateral mixing in tubular reactors has proven useful in a number of experiments conducted in flow [1].

Above: A schematic and picture of the setup for measuring diffusion/ mixing in

flow using a Syrris Asia syringe pump and Mettler Toledo ReactIR FD.

We have also investigated the use of the AM Technology Coflore® agitating cell reactor which uses a transverse mixing motion to keep solids in suspension [2]. The flow device delivered 208 g of N-iodomorpholinium hydroiodide salt over a 9 hour period (equating to 3.88 kg/week) under optimized conditions. The reactor is suitable for the medium-scale (5 kg) processing of solid-forming reactions and appears to offer the potential for a variety of more complex applications.

Also see our work below on ultrasound for alternative mixing solutions.

Publications

1. Continuous stream processing: a prototype magnetic field induced flow mixer Green Process. and Synth. 2012, 1, 11-18

P. Koos, D.L. Browne and S.V. Ley*

2. Continuous flow processing of slurries: evaluation of an agitated cell reactor Org. Proc. Res. Dev. 2011, 15, 693-697

D.L. Browne, B.J. Deadman, R. Ashe, I.R. Baxendale, S.V. Ley*

Ultrasound

The use of ultrasound techniques in flow

In recent work we describe the efficient and easily scalable transformation for converting alcohols and aldehydes to carboxylic acids and nitroalkane derivatives to the corresponding carbonyls and carboxylic acids using potassium permanganate as the oxidant within a continuous flow reactor [1]. Notably, the downstream processing of precipitated manganese dioxide in this application required the use of ultrasonics to ensure an even flow pattern and avoid fouling and blocking of the system.

Publications

1. KMnO4 mediated oxidation as a continuous flow process

J. Sedelmeier, S.V. Ley, I.R. Baxendale, M. Baumann, Org. Lett. 2010, 12, 2618-3621

EARLY WORK

Ultrasound in synthesis, reactivity and structure concepts in organic chemistry Vol. 27, Verlag, Berlin, Heidelberg, New York, 1989. (ISBN 3-540-51023-0).

Ultrasonic formation and Reactions of Sodium Phenylselenide

S.V. Ley, I.A. O’Neil and C.M.R. Low, Tetrahedron 1986, 42, 5363-5368

Application of ultrasound to the preparation of tricarbonyliron diene complexes

S.V. Ley, C.M.R. Low and A.D. White, J. Organometallic Chem. 1986, C13-C16

Enabling Tools Reviews

Organic Synthesis: March of the Machines Organic synthesis is changing; in a world where budgets are constrained and the environmental impacts of practice are scrutinized, it is increasingly recognized that the efficient use of human resource is just as important as material use. New technologies and machines have found use as methods for transforming the way we work, addressing these issues encountered in research laboratories by enabling chemists to adopt a more holistic systems approach in their work. Modern developments in this area promote a multi-disciplinary approach and work is more efficient as a result. This Review focuses on the concepts, procedures and methods that have far-reaching implications in the chemistry world. Technologies have been grouped as topics of opportunity and their recent applications in innovative research laboratories are described.

Angew. Chem. Int. Ed. 2015, 54, 3449-3464, S.V. Ley, D.E. Fitzpatrick, R.J. Ingham, R.M. Myers

Flow Chemistry: Intelligent Processing of Gas-Liquid Transformations using a Tube-in-Tube Reactor This Account examines our efforts toward the development of a simple, unified methodology for the processing of gaseous reagents in flow by way of development of a tube-in-tube reactor device and applications to key C–C, C–N, and C–O bond forming and hydrogenation reactions. We further describe the application to multistep reactions using solid-supported reagents and extend the technology to processes utilizing multiple gas reagents. A key feature of our work is the development of computer-aided imaging techniques to allow automated in-line monitoring of gas concentration and stoichiometry in real time. We anticipate that this Account will illustrate the convenience and benefits of membrane tube-in-tube reactor technology to improve and concomitantly broaden the scope of gas/liquid/solid reactions in organic synthesis.

Acc. Chem. Res. 2015, 48, 349-362, M. Brzozowski, M. O’Brien, S.V. Ley, A. Polyzos

Flow Chemistry Meets Advanced Functional Materials Flow chemistry and continuous processing techniques are beginning to have a profound impact on the production of functional materials ranging from quantum dots, nanoparticles and metal organic frameworks to polymers and dyes. These techniques provide robust procedures which not only enable accurate control of the product material’s properties but they are also ideally suited to conducting experiments on scale. The modular nature of flow and continuous processing equipment rapidly facilitates reaction optimisation and variation in function of the products.

Chem. Eur. J. 2014, 20, 12348-12366, R.M. Myers, D.E. Fitzpatrick, R.M. Turner, S.V. Ley

Camera Enabled Techniques for Organic Synthesis A great deal of time is spent within synthetic chemistry laboratories on non-value-adding activities such as sample preparation and work-up operations, and labour intensive activities such as extended periods of continued data collection. Using digital cameras connected to computer vision algorithms, camera-enabled apparatus can perform some of these processes in an automated fashion, allowing skilled chemists to spend their time more productively. In this review we describe recent advances in this field of chemical synthesis and discuss how they will lead to advanced synthesis laboratories of the future.

Beilstein J. Org. Chem. 2013, 9, 1051-1072, S.V. Ley, R.J. Ingham, M. O’Brien, D.L. Browne

Flow Microwave Technology and Microreactors in Synthesis A bespoke microwave reactor with a glass containment cell has been developed for performing continuous flow reactions under microwave heating. The prototype unit has been evaluated using a series of standard organic chemical transformations enabling scale-up of these chemical processes. As part of the development, a carbon-doped PTFE reactor insert was utilized to allow the heating of poorly absorbing reaction media, increasing the range of solvents and scope of reactions that can be performed in the device.

Aust. J. Chem., 2013, 66, 131-144, I.R. Baxendale, C. Hornung, S.V. Ley, J. de M. Muñoz Molina, A. Wikström

Lesser-known Enabling Technologies for Organic Synthesis In this review we summarise both new emerging technologies as well as some overlooked methods which are beneficial to a variety of synthesis applications. Separation Methods: Low-Temperature Chromatography; Reflux Chromatography; Phase-Switching Methods e.g. Affinity-Based Phase-Switching, Fluorous Tags, Acid-Base and Polarity Tags, Transition-Metal and Ligand Affinity Tags; Hydrogen-Bonding Interactions, Polyaromatic Affinity Tags, Crown Ether Tags; Redox-Switchable Tags; Reactive and Irreversible Tags e.g. Click Tags, Diels-Alder Tags; Phase-Switching Involving Precipitation e.g. Precipitation by Polymerisation, Solubility-Switching, Temperature-Dependent Solubility; Size-Exclusion Tags. Synthesis Methods: Cooled Microwave Heating; Ball-Milling; Design of Experiments and Related Techniques.

Synthesis 2011, 1157-1192, M. O’Brien, R. Denton and S.V. Ley

Lab of the Future: the Importance of Remote Monitoring and Control Chemical laboratories and the equipment within them have changed very little over the last two centuries. However, the introduction of enabling technologies and their impact on current working practices is starting to redefine the laboratory environment. In this article the application of remote control software applied to real applications of flow-based synthesis are demonstrated and the related improvements in efficiency and safety discussed. The use of webcams to remotely monitor synthetic procedures is described along with the associated enhancements that can be achieved.

Chim. Oggi./Chemistry Today 2011, 29, 28-32, M.D. Hopkin, I.R. Baxendale and S.V. Ley